|

Details

Product Description | Surface Finish | Definition | Application | | 2B | Finished by heat treatment , picking or equipvalent cold rolling , followed by skin pass to obtain adequate luster surface. | With bright and smooth surface ,easy for further grinding to obtain brighter surface ,suitable for medical instruments ,milk containers ,tableware and so on. | | BA | Bright heat treatment after cold rolling. | Structual members .etc.kitchen utensil ,cutlery ,eleltric applicances ,medical instruments ,building decorations ,etc. | | NO.3/NO.4 | Polished with No.150-240 abrasives. | Milky food processing equipment , medicalinstruments ,building decorations. | | HL | Finshed by polishing with abrasives of suitable grain size to obtain continuous streaks. | Building decorations ,such as elevators ,escalators ,door etc. | | 6K/8K | A mirror-like reflective surface ,which is obtained by polishing with successively finer abrasives and buffing extensively with all gritlines are removed. | Buliding entrances,bulkding column casting ,elevator's wall doors ,counters,sculptures etc. |

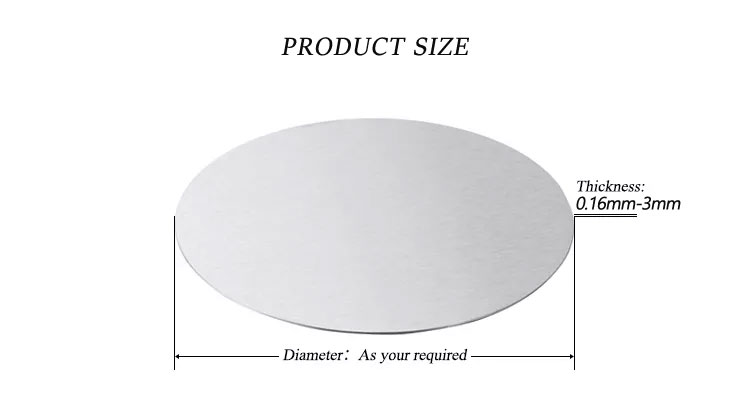

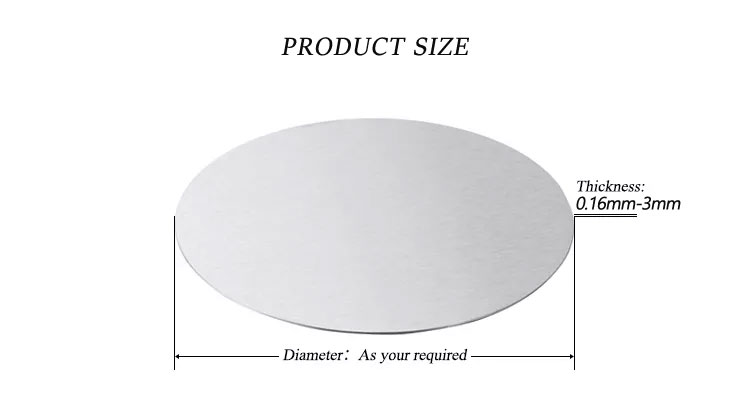

What Product Description of our Stainless Steel circle? Product name | Stainless Steel Coil, Stainless Steel Roll, Stainless Steel Strip | Material | Ferrite stainless steel, magnetic. | Standard | AISI, ASTM, EN, GB, DIN, JIS | HR Origin | TISCO /JISCO /BAOSTEEL | Grade | 410S, 410L,410, 430, 409L, 201 | Form | Cold Rolled Treatment, soft material | Thickness | 0.16mm -3mm | Width | 55mm-980mm | Length | As request, Coil | Surface | No.1, 2D, 2B, NO.4, HL(Hairline),8K, BA | Hardness | Full hard, Soft, Semi-DDQ, DDQ (Deep drawing quality) | More Process | Paper Insert, PVC coated, slit edge, circle cutting | Packing | Exporting wooden pallet | Normal Lead Time | 10-40days after deposit received | Payment Term | T/T, Irrevocable L/C at sight | ü The sizes or thicknesses of stainless steel coil can be customized, if you need additional information, please don’t hesitate to contact us at any time. ü All standard products are supplied without inter paper & PVC film. If needed, please inform. |

| Chemical composition and mechanical properties of stainless steel circle | | Grade | Chemical Composition (%) | Mechanieal Performece | | C | Si | Mn | P | S | Ni | Cr | Mo | Hardness | | 201 | ≤0.15 | ≤1.00 | 5.5/7.5 | ≤0.060 | ≤0.030 | 3.5/5.5 | 16.0/18.0 | - | HB≤241,HRB≤100, HV≤240 | | 304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.0/11.0 | 18.00/20.00 | - | HB≤187,HRB≤90,HV≤200 | | 410 | ≤0.15 | ≤1.00 | ≤1.25 | ≤0.060 | ≤0.030 | ≤0.060 | 11.5/13.5 | - | HB≤183, HRB≤88 HV≤200 | | 430 | ≤0.12 | ≤1.00 | ≤1.25 | ≤0.040 | ≤0.03 | - | 16.00/18.00 | - | HB≤183, HRB≤88 HV≤200 |

What Detailed Images of our Stainless Steel circle?

|

|